The ClimateCrete™ Revolution

Re-engineered sand for stronger, climate-friendly concrete

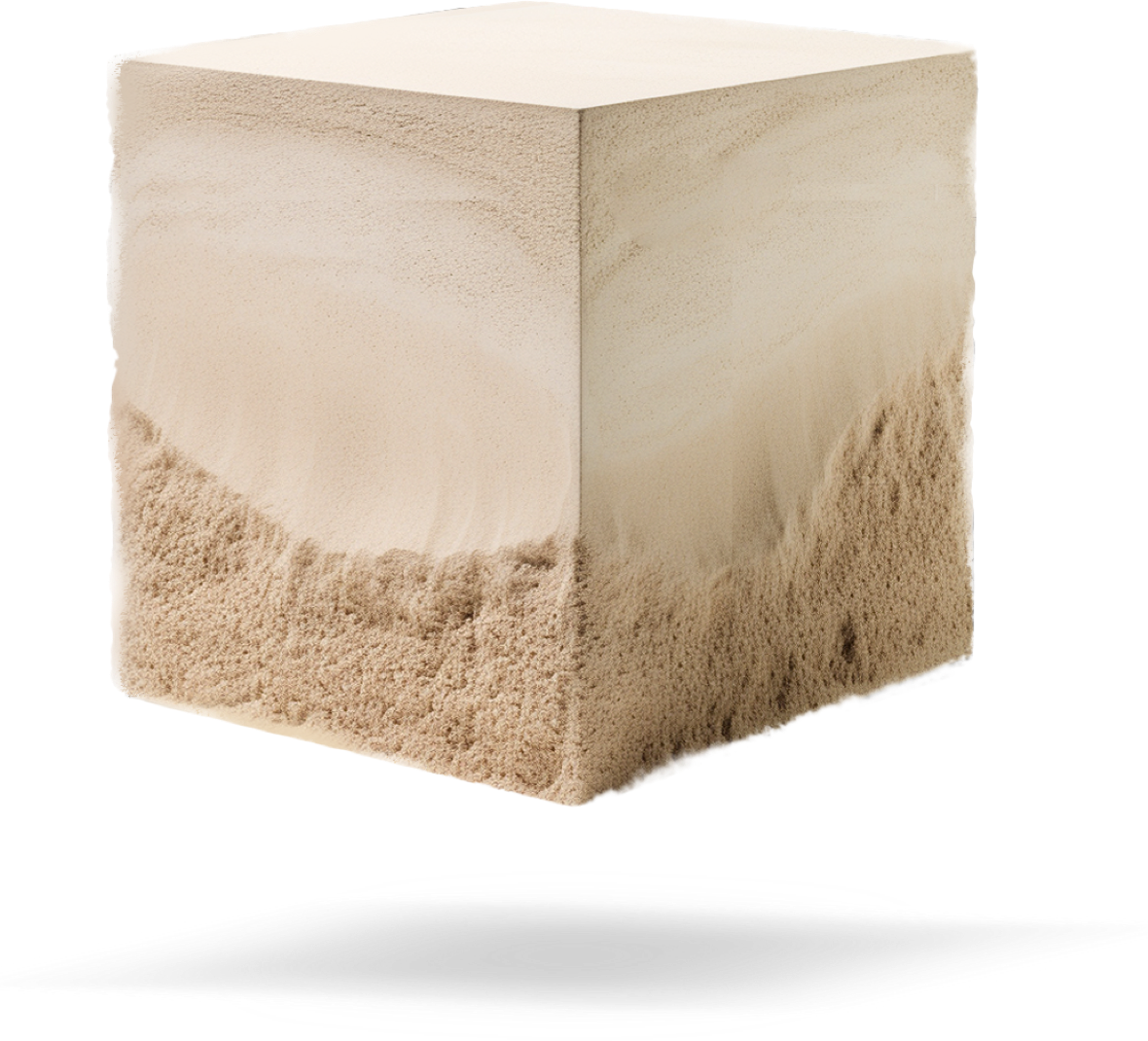

Re-engineered Sand

The ClimateCrete™ technology turns the fine, smooth grains of weathered desert sand into concrete ready aggregate at a cost per ton no more than the cost of imported sand. The process is safe, requires little water, leaves no by-products and is proven at multi-ton scale.

Stronger, Climate-friendly Concrete

ClimateCrete™ concrete has equal or greater compressive strength* and can be formulated with significantly less cement, which contributes most of concrete’s CO2 footprint. Together with the elimination of CO2 emissions associated with sand imports, ClimateCrete can reduce concrete’s carbon footprint by half or more.

First, Saudi Arabia, then the globe

ClimateCrete is working with major construction partners in Saudi Arabia on testing and commercial deployments using the Arabian peninsula’s bountiful, indigenous sands. Ultimately, the aim is to enter the global, $400 billion construction aggregates market.

A KAUST Spinout

The ClimateCrete™ technology was developed in the laboratory of Dr. Jorge Gascon, a Professor and Director at Saudi Arabia’s KAUST Catalysis Center, where he worked with co-founder William McDonough, a KAUST Distinguished Researcher Professor.

A Silicon Valley-based firm

Though founded in Saudi Arabia based on research at KAUST, ClimateCrete is incorporated in Delaware and based in Silicon Valley, where its CEO, Peter Hadrovic, resides.

*As tested by the Max Planck Institute for Materials Testing and Development using the DIN EN 196 procedure.