Solving Concrete’s Sand Problem

ClimateCrete is revolutionizing concrete production by making locally excavated material and desert sand into aggregates suitable for concrete production, thereby ending the construction industry’s dependency on costly, environmentally damaging sand imports. ClimateCrete’s formulation greatly reduces concrete’s carbon footprint and yields a competitively priced upgrade to conventional concrete.

Using Local Sand Makes Better Concrete For The Planet

Starting in Saudi Arabia, where ClimateCrete’s technology was developed

Sand is the most-consumed natural resource on the planet besides water. People use some 50 billion tonnes of “aggregate” – the industry term for sand and gravel, which tend to be found together – every year.

The overwhelming bulk of the sand we harvest goes to make concrete, and for that purpose, desert sand grains are the wrong shape. Eroded by wind rather than water, they are too smooth and rounded… The sand we need is the more angular stuff found in the beds, banks, and floodplains of rivers. The demand is so intense that around the world, riverbeds and beaches are being stripped bare, and farmlands and forests torn up to get at the precious grains.

BBC Future, “Why the world is running out of sand”

THE CHALLENGE

Soaring Demand

Rapid urbanization has sent global demand for concrete soaring. In Saudi Arabia alone, more than a trillion dollars in new construction is in development due in part to the Kingdom’s ambitious NEOM project. Saudi Arabia already imports more than 30 million tons of sand per year, and demand is outstripping supply.

Climate Impact

Shipping sand by sea to Saudi Arabia is costly, and the marine carriers are a major source CO2. The marine heavy fuel oil burned in bulk carriers generate on average 1.5 tons of CO2 emissions per ton of sand. Likewise, sand quarried in Saudi Arabia is trucked long distances to construction sites, creating another major source of CO2 emissions.

Environmental Degradation

The “sand rush” globally is leading to the degradation of important ecosystems in Asia, such as the Mekong Delta, where rivers, beaches, and lake beds are ruthlessly exploited for their increasingly valuable concrete-ready sands. At the same time, construction sites around Saudi Arabia have vast, untapped reserves of excavated materials that can be transformed into aggregate for concrete.

The ClimateCrete Solution

At Saudi Arabia’s King Abdullah University for Science and Technology (KAUST), scientists have developed a technology that can make nearly any type of sand or excavated material into concrete-ready aggregate with highly competitive economics. KAUST spun out ClimateCrete to commercialize the groundbreaking technology.

ClimateCrete Co-Founders

ClimateCrete is the result of a long-term collaboration between a Chemical Engineer and a World-famous Architect.

ClimateCrete is the fruit of a long-term collaboration at King Abdullah University of Science and Technology (KAUST) between a Chemical Engineer Dr. Jorge Gascon and a world-famous architect William McDonough, FAIA, INT. FRIBA, both deeply committed to addressing resource depletion and global warming.

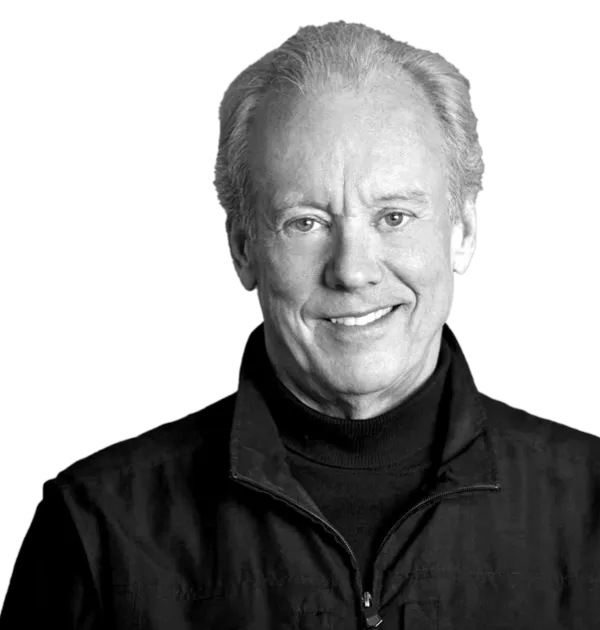

William McDonough

Jorge

Gascon